In HVAC systems, electric fire dampers are crucial components designed to prevent the spread of fire and smoke through ductwork. Here’s a breakdown of their function, types, and applications:

1. What is an Electric Fire Damper?

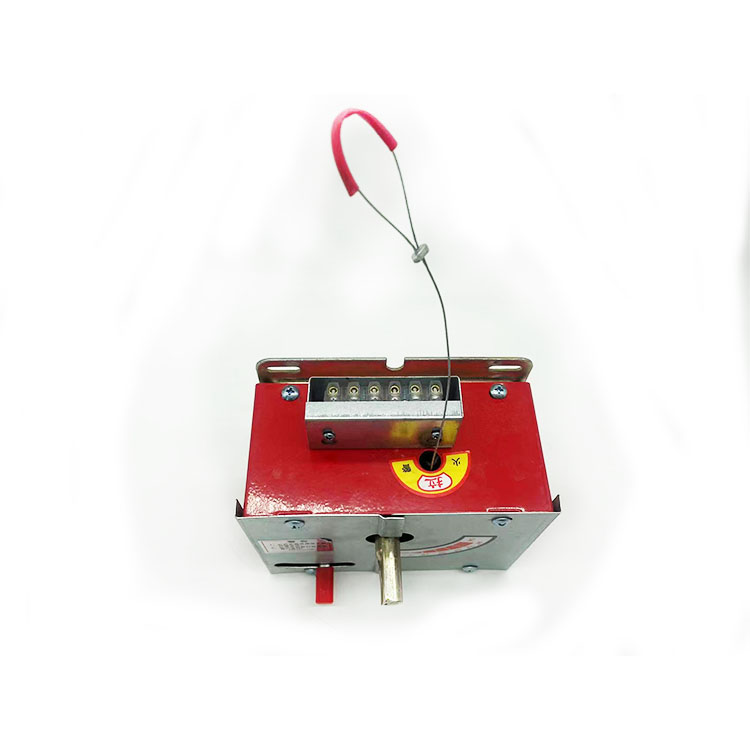

An electric fire damper is a device installed in HVAC ducts that automatically closes when triggered by a fire alarm or high temperatures, blocking flames and smoke from spreading to other parts of a building.

2. How It Works

Activation:

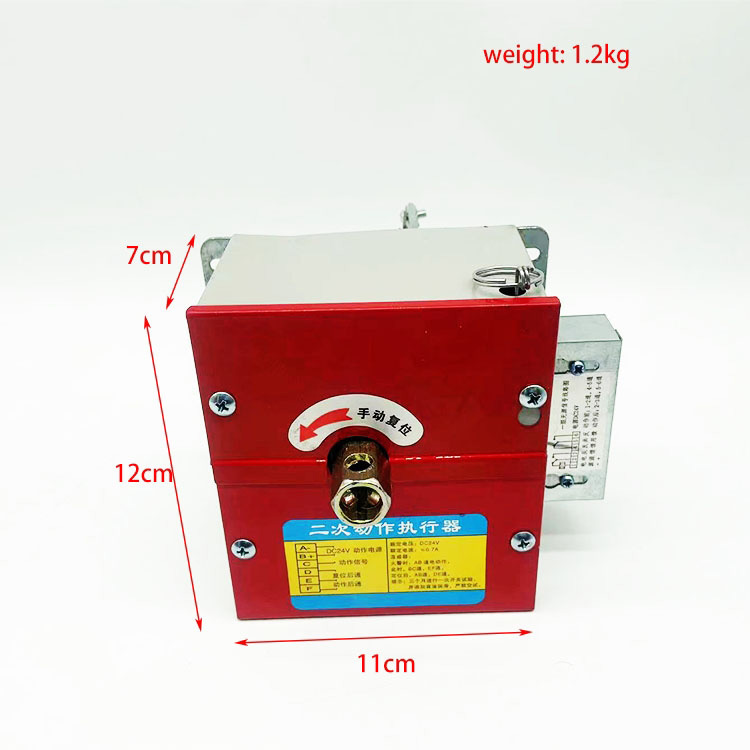

Electric Release: Connected to a fire alarm system, the damper closes when power is cut (failsafe) or when a signal is sent.

Thermal Fusible Link: Some models also have a heat-sensitive element that melts at high temperatures (typically 165°F/74°C or higher), causing the damper to close mechanically.

Operation: A motor or spring mechanism shuts the damper blades when activated.

3. Types of Fire Dampers

Static (Non-Combination) Fire Dampers: Close to stop fire/smoke but do not restrict airflow when open.

Dynamic (Combination) Fire Dampers: Can withstand airflow pressure (used in systems with fans that may continue running during a fire).

Smoke Dampers: Often paired with fire dampers to control smoke migration (activated by smoke detectors).

4. Applications

Installed in fire-rated walls/floors where ducts penetrate.

Used in commercial buildings (hospitals, schools, high-rises) per NFPA 90A, IBC, and local fire codes.

Commonly found in supply, return, and exhaust ducts.

5. Electric vs. Pneumatic vs. Spring-Return

Electric: Uses an actuator/solenoid; ideal for integration with building fire alarm systems.

Pneumatic: Uses air pressure (less common today).

Spring-Return: Mechanical, closes when a fusible link breaks.

6. Testing & Maintenance

Required annually per NFPA 80 & NFPA 105.

Check for:

Proper closure (no obstructions).

Electrical connections (if applicable).

Fusible link integrity.