-

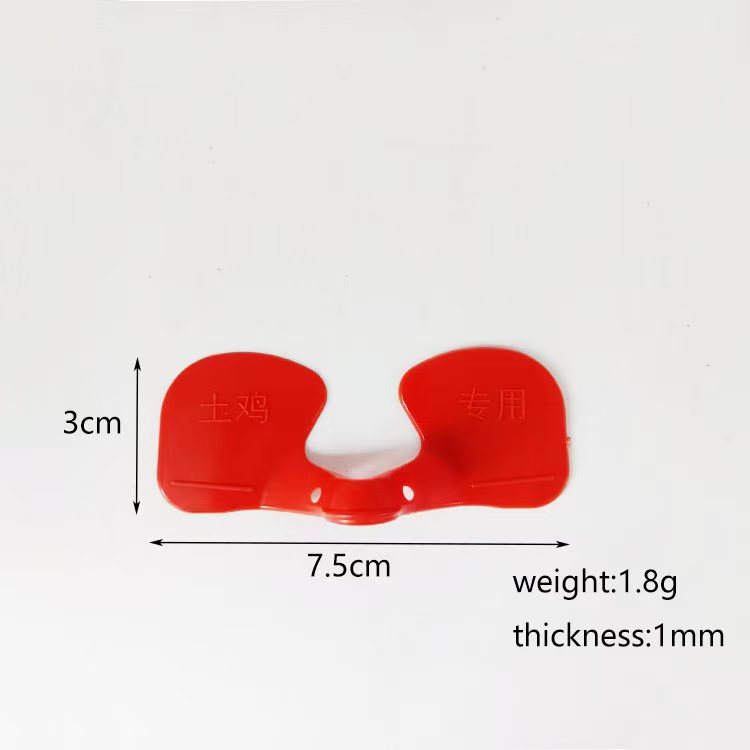

Chicken Glasses

Chicken Glasses

Chicken Glasses for Anti-Fighting, Anti-Pecking & Anti-Toe-Pecking...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

What factors can affect the accuracy of hardware stretching parts?

Apr 18

2025

There are many factors that affect the accuracy of hardware stretching parts, including mold accuracy, material characteristics, equipment performance, process parameters, and operator level. The following is a specific introduction:

In terms of molds

Mold manufacturing accuracy: The machining accuracy of the mold directly determines the accuracy of the stretched part. If the dimensional accuracy of the mold cavity is low and the surface roughness is high, the dimensional deviation of the stretched part will be large, and the surface will not be smooth.

Mold wear: During the stretching process, there is strong friction between the mold and the material, and the mold will wear out after prolonged use. Especially in areas such as rounded corners and edges, wear can cause changes in mold dimensions, thereby affecting the accuracy of the stretched parts.

Mold assembly accuracy: The accuracy of assembling various components of the mold has a significant impact on the precision of the stretched parts. For example, the parallelism of the upper and lower mold seats, the accuracy of the guiding mechanism, etc., if not assembled properly, can cause the mold to deviate during the stretching process, resulting in defects such as eccentricity and distortion of the stretched parts.

In terms of materials

Material thickness tolerance: Uneven material thickness can lead to inconsistent deformation in various parts during the stretching process. Materials with large thickness deviations may experience dimensional instability and irregular shapes after stretching, which can affect the accuracy of the stretched parts.

Uneven mechanical properties of materials: If there are significant differences in mechanical properties such as strength, hardness, and elongation of materials, the degree of deformation in different parts during stretching will vary, which can easily lead to defects such as local tearing and wrinkling, thereby affecting the accuracy and quality of the stretched parts.

Equipment aspect

Accuracy of the press: The accuracy of the slider movement and pressure stability of the press have a significant impact on the accuracy of the stretching parts. If the sliding block of the press moves unevenly, it will cause uneven tensile force, resulting in problems such as uneven deformation and dimensional deviation of the stretching parts.

Insufficient rigidity of the equipment: During the stretching process, if the rigidity of the equipment is not sufficient, it will undergo elastic deformation under high pressure, which will cause changes in the actual working clearance of the mold and affect the dimensional and shape accuracy of the stretched parts.

In terms of process parameters

Stretching ratio: If the stretching ratio is too large, the material will deform too much during the stretching process, which can easily exceed the plastic deformation limit of the material, leading to defects such as tearing and thinning, affecting the accuracy and quality of the stretched parts.

Edge pressure: The edge pressure is too small to effectively prevent the material from wrinkling during the stretching process; Excessive edge pressure can increase the friction between the material and the mold, leading to material strain, thinning, and even tearing, which can have a negative impact on the accuracy of the stretched parts.

Stretching speed: If the stretching speed is too fast, the material cannot deform uniformly in time, which can easily lead to local stress concentration, resulting in tensile cracking or uneven deformation; If the stretching speed is too slow, it will affect production efficiency. The appropriate stretching speed is crucial for ensuring the accuracy and quality of the stretched parts.

In terms of operators

Process development ability: If the operator does not develop a reasonable processing technology based on factors such as the material, shape, and size of the stretched part, such as selecting inappropriate stretching times and mold gaps, it will lead to various problems during the stretching process, affecting the accuracy of the stretched part.

Proficiency in operation: The proficiency and skill level of operators in mold installation, equipment debugging, feeding, and other processes can also affect the accuracy of the stretched parts. For example, improper installation of the mold during mold installation, delayed or inaccurate feeding, etc., may all lead to quality problems with the stretched parts.