Water Level Controllers for Pig Farms

A water level controller is a device used in livestock farms to automatically regulate water levels in pig shed drinking equipment. Its primary functions include maintaining stable water levels in drinking troughs, preventing water waste, and ensuring pigs always have access to clean drinking water. The following details its working principles, types, characteristics, installation/maintenance guidelines, and applications:

I. Working Principles

Pig water level controllers typically operate based on buoyancy principles or pressure sensing technology:

1. Buoyancy-Type Water Level Controllers

Core Components: Float ball, connecting rod, and inlet valve.

Mechanism:When water level in the trough drops, the float ball sinks with the water, triggering the inlet valve to open via the connecting rod, allowing water to flow in.

As the water level rises to the preset height, the float ball rises and pushes the valve to close, stopping water supply.

2. Pressure-Type Water Level Controllers

Mechanism:Pressure sensors monitor water levels. When the level drops below the set value, the sensor activates a solenoid valve to start water supply.

The valve closes once the preset water level is reached.

Some intelligent models can connect to control systems for remote monitoring and automatic adjustment.

II. Main Types

Classified by structure and application scenarios:

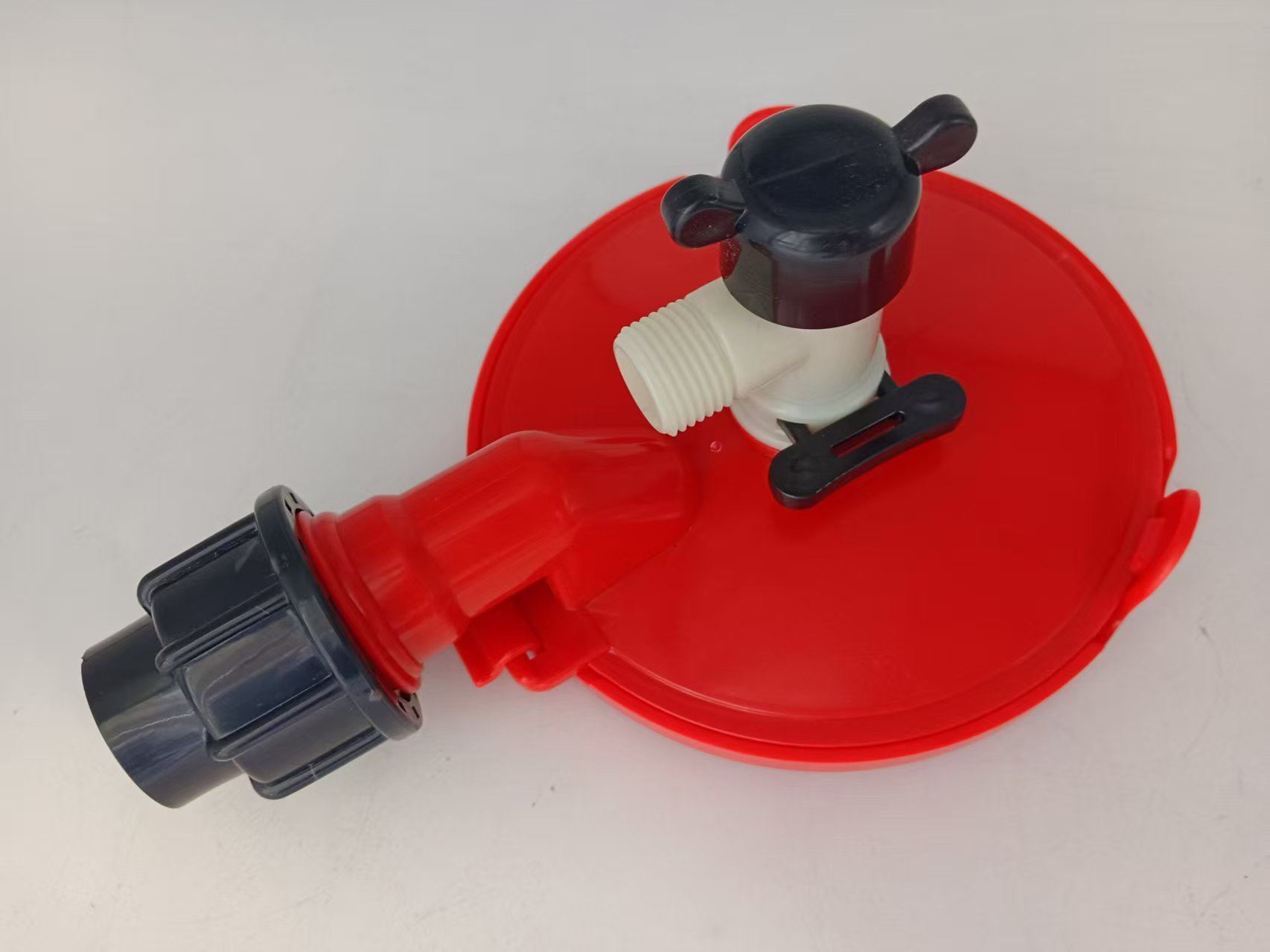

TypeCharacteristicsApplication Scenarios

Float-Type Controller Simple structure, low cost, easy maintenance, but lower precision (prone to float jams). Small-to-medium pig farms, traditional sheds.

Duck-Bill Controller Duck-bill-shaped outlet dispenses water when triggered by pigs, reducing waste and maintaining cleanliness. Nursery and growing pig sheds.

Nipple-Type Controller Small outlet requires pigs to lick for water, excellent water-saving effect, suitable for automatic systems. Large-scale farms, intelligent breeding environments.

Smart Inductive Controller Integrated sensors and control systems for real-time water level/