-

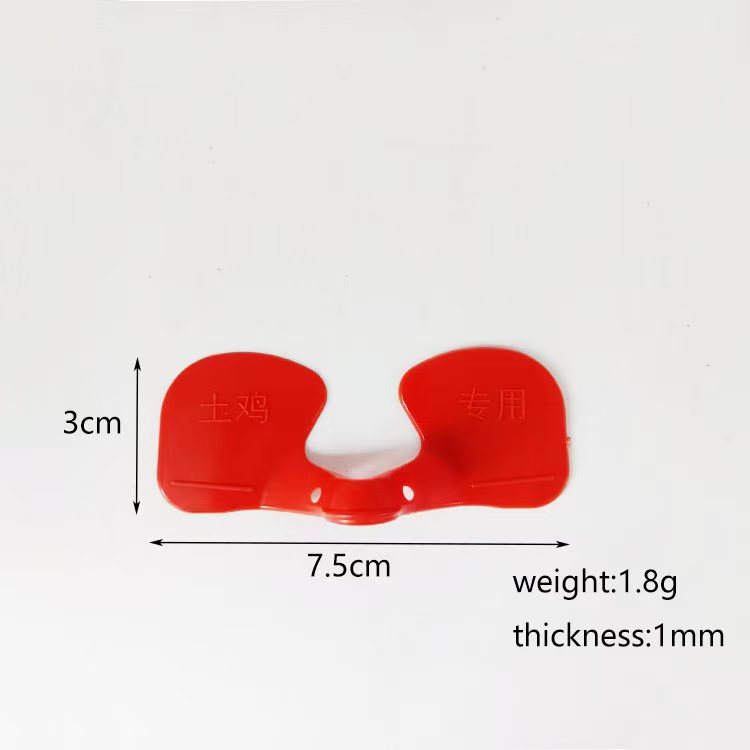

Chicken Glasses

Chicken Glasses

Chicken Glasses for Anti-Fighting, Anti-Pecking & Anti-Toe-Pecking...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

Hardware stretching parts: from basic craftsmanship to complex shape shaping

Apr 12

2025

The process of shaping hardware stretching parts from basic technology to complex shapes involves multiple technologies and techniques. The following is a related introduction:

Basic process

Material selection: Choose the appropriate material based on the usage requirements and performance characteristics of the stretching parts. Common ones include low-carbon steel, stainless steel, aluminum alloy, etc. For example, 08 steel has a lower price and good stamping performance, making it suitable for general tensile parts; Stainless steel has good corrosion resistance and is commonly used in tensile parts that require corrosion resistance.

Preparation of raw materials: First, calculate the size of the raw materials. For simple shaped rotating stretching parts, the calculation can be based on the principle that the blank area is equal to the stretching part area. Then proceed with cutting, cutting the board into the desired blank shape and size. Common cutting methods include cutting, punching, etc.

Stretch mold design and manufacturing: The mold is the key to the stretching process. When designing a mold, it is necessary to determine the dimensions, fillet radius, clearance, and other parameters of the convex and concave molds. When manufacturing molds, it is necessary to ensure the machining accuracy and surface quality of the molds. Usually, CNC machining, electrical discharge machining and other processes are used to ensure the accuracy of the molds.

Stretching processing: Place the blank in a stretching mold and apply external force through a press, causing the blank to undergo plastic deformation under the action of the convex and concave molds, gradually forming the desired shape of the stretched part. During the stretching process, it is necessary to reasonably control process parameters such as stretching coefficient, edge pressure, and stretching speed.

Complex shape shaping

Multiple Stretching: For deep and complex shaped stretching parts, it is difficult to complete them in one stretch and multiple stretching processes are required. By gradually increasing the number of stretches, with an appropriate amount of deformation per stretch, the blank gradually approaches the final complex shape. For example, some deep cylindrical or stepped stretching parts usually require 2-3 or even more stretches to form.

Special stretching process

Thinning and stretching: During the stretching process, by reducing the gap between the convex and concave molds, the thickness of the cylinder wall of the stretched part is reduced, thereby improving the accuracy and strength of the stretched part. At the same time, some special shape requirements can also be achieved, such as ultra thin walled containers or parts with specific wall thickness distributions.

Reverse stretching: Place the stretched workpiece from the previous process in reverse into the mold for further stretching, so that the inner side of the workpiece becomes outer and the outer diameter becomes smaller. This method can increase radial tensile stress, help prevent wrinkling, and enable the formation of some internally complex shaped stretching parts.

Combining with other processes

Bulging: During or after stretching, the stretched part is subjected to bulging treatment, by applying pressure internally to expand the local area of the stretched part outward, forming complex curved or convex shapes. For example, large coverings such as car engine hoods are usually subjected to bulging processes after stretching to improve their rigidity and appearance quality.

Bending: For some complex stretching parts with bending characteristics, stretching can be carried out first, and then the required bending part can be formed through bending technology. For some U-shaped or L-shaped stretching parts, they are first stretched into a rough shape and then bent into shape using a bending mold.

Mold optimization and adjustment: For complex shaped stretching parts, the design and manufacturing of molds are difficult, and continuous optimization and adjustment of molds are required. Special structures such as stretching bars and process cuts may need to be installed on the mold to control material flow and prevent defects such as wrinkling and tearing.

Quality Control and Testing

Appearance inspection: mainly inspect the surface quality of the stretched parts, such as whether there are defects such as scratches, cracks, wrinkles, deformation, etc. For stretch parts with high appearance requirements, it may be necessary to use equipment such as optical microscopes or electron microscopes for microscopic inspection.

Dimensional accuracy measurement: Measuring the key dimensions of the stretched part using measuring tools such as calipers, micrometers, coordinate measuring instruments, etc., to ensure that the dimensional deviation is within the tolerance range required by the design. For complex shaped stretching parts, a coordinate measuring instrument can quickly and accurately measure the dimensions of each part, making it easy to adjust and optimize the mold.

Performance testing: Conduct corresponding performance testing based on the usage requirements of the stretched parts, such as hardness testing, strength testing, toughness testing, etc. For example, for tensile parts that withstand high pressure, strength testing is required to ensure that they will not rupture or deform during use.