-

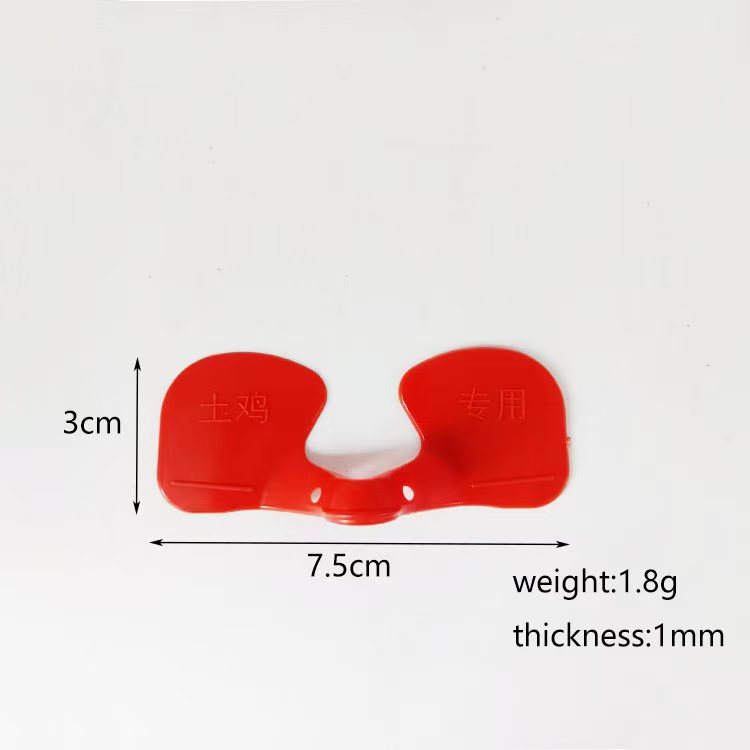

Chicken Glasses

Chicken Glasses

Chicken Glasses for Anti-Fighting, Anti-Pecking & Anti-Toe-Pecking...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Water Level Controller

Water Level Controller

Water Level Indicator is a device designed to monitor the liquid level (e.g., water, oil) in a tank ...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

-

Hay Feeder

Hay Feeder

Hay Feeder – Product Introduction Product Overview A Hay Feeder is a specialized equipment designed...

Defects in the appearance and common processing problems of metal stamping parts

Apr 12

2025

Inspection methods and specifications for appearance defects of metal stamping parts:

1.Wrinkle inspection method:It is not allowed to have all the wrinkles that consumers can easily notice on the outer cover,and it is not allowed to have more serious wrinkles on the inner cover that may cause raw material stacking.

2.Shrinkage inspection method:observe and dissect.Shrinkage is a potential risk cracking point in the entire process of forming metal stamping parts,which has a particularly important impact on the function,compressive strength,and fatigue resistance of metal stamping parts.Determine whether the metal stamping parts meet the standard,repair,damage,etc.based on the level of diameter reduction.

3.Inspection methods for calendering,embossing,and scratching:The outer surface layer of the cover should not have any calendering,scratching,or embossing;The inner surface of the outer cover shall not have scratches or imprints that may harm the performance of the external process.The surface of the inner cover must not have potentially serious scratches or imprints that could cause the parts to crack.

4.Rust inspection method:observe and dissect.Rust is caused by long-term storage or poor storage of metal stamping parts,which poses a particularly important threat to their performance,compressive strength,and fatigue resistance.

5.Inspection method for non-conforming arcs:Look at and accurately measure the semicircle of the arc using fixtures,which may not be symmetrical or clear about the main bridge.External coverings are not allowed to exist,and some installation surfaces and steel bar overlap surfaces of internal coverings have unsatisfactory arcs,which not only endanger the appearance of metal stamping parts,but also pose a serious threat to welding and installation.

6.Pit package inspection method:Watch.The existence of pit packaging poses a serious threat to the appearance quality of the covered parts after painting,which is a defect that customers cannot tolerate.Large scale potholes will continue to harm the compressive strength and fatigue value of metal stamping parts,and cannot be repaired.

7.Edge inspection method:The length of the edge should be less than 10%of the thickness of the board.All hazards of welding,welding edges that conform to horizontal burrs are unacceptable.All burrs that are prone to causing accidental injury are unacceptable.Punching machine burrs that accurately locate and install all hazardous parts are not acceptable.

8.Crack inspection method:Look at it.It is unacceptable for all external coverings to rupture completely.For minor cracks in the inner cover,welding repair is allowed,but the repair location is not easy to detect and needs to consider the repair specifications for metal stamping parts.

9.Inspection method for defects in raw materials:According to the specifications,the compressive strength of the raw materials does not meet the requirements.There are imprints,overlaps,orange peel,gray spots,loose hot-dip galvanized surface,and peeling hot-dip galvanized layer left on the rolled steel plate.

Problems encountered in the processing of sheet metal stamping parts:

1.When stamping and bending soft materials such as copper and aluminum alloys in continuous operation,metal particles or residues are prone to adhere to the surface of the working area,causing large scratches on the object.At this time,carefully analyze the shape and lubricating oil of the working area to generate particles and residues in the blank without causing scratches.

2.The radius of the concave die corner is too small,and there are impact marks on the bent part of the metal stamping.Polishing the concave die and increasing the fillet radius of the concave die can prevent scratches on metal stamping bent parts.

3.The gap between the convex and concave molds should not be too small,as a small gap can cause thinning and scratching.During the stamping process,it is necessary to constantly check the changes in the clearance of the mold.

4.When the convex mold enters the concave mold too much,it will cause scratches on the surface of the parts.Therefore,without being affected by rebound,the amount of convex mold entering the concave mold should be appropriately reduced.

5.When the burr surface is used as the outer surface for metal stamping and bending,the workpiece is prone to cracking and scratching;Therefore,when metal stamping and bending,the burr surface should be used as the inner surface of the metal stamping and bending.

6.In order to meet the requirements of wood processing accuracy,the metal stamping and bending method of bottom stamping material is often used.Therefore,when metal stamping bends,the springs,position pin holes,plate and return holes on the raw material plate are affected.Becoming an indentation,therefore,adjustments should be made.

7.When the bending direction of metal stamping is parallel to the rolling direction of the material,cracks will appear on the surface of the part,thereby reducing the surface quality of the workpiece.When the metal stamping bending exceeds two parts,the angle between the metal stamping bending direction and the rolling direction should be maximized.

5、Metal stamping parts have good dimensional accuracy,uniform dimensions with the same module,and good interchangeability.No further mechanical processing is required to meet the general installation and application requirements.During the stamping process,metal stamping parts have good appearance quality and a smooth and beautiful appearance because the surface of the material is not damaged.This provides convenient conditions for surface painting,electroplating,phosphating,and other surface treatments.